High voltage (HV) testing is an essential aspect of modern power distribution, playing a pivotal role in ensuring reliability and safety in electrical systems. As our reliance on electricity grows, so does the need for rigorous testing methods that can identify potential failures before they manifest into costly outages or dangerous situations.

Various HV testing techniques, such as dielectric withstand testing, insulation resistance testing, and partial discharge measurement, serve distinct purposes and are employed at different stages of equipment life cycles.

Each method provides unique insights into the condition of electrical components, empowering engineers and technicians to make informed maintenance decisions. By exploring the different HV testing methods and their diverse applications, we can appreciate how these practices contribute not only to the longevity of power infrastructure but also to the overall stability of the electrical grid.

Types of High Voltage Testing Methods

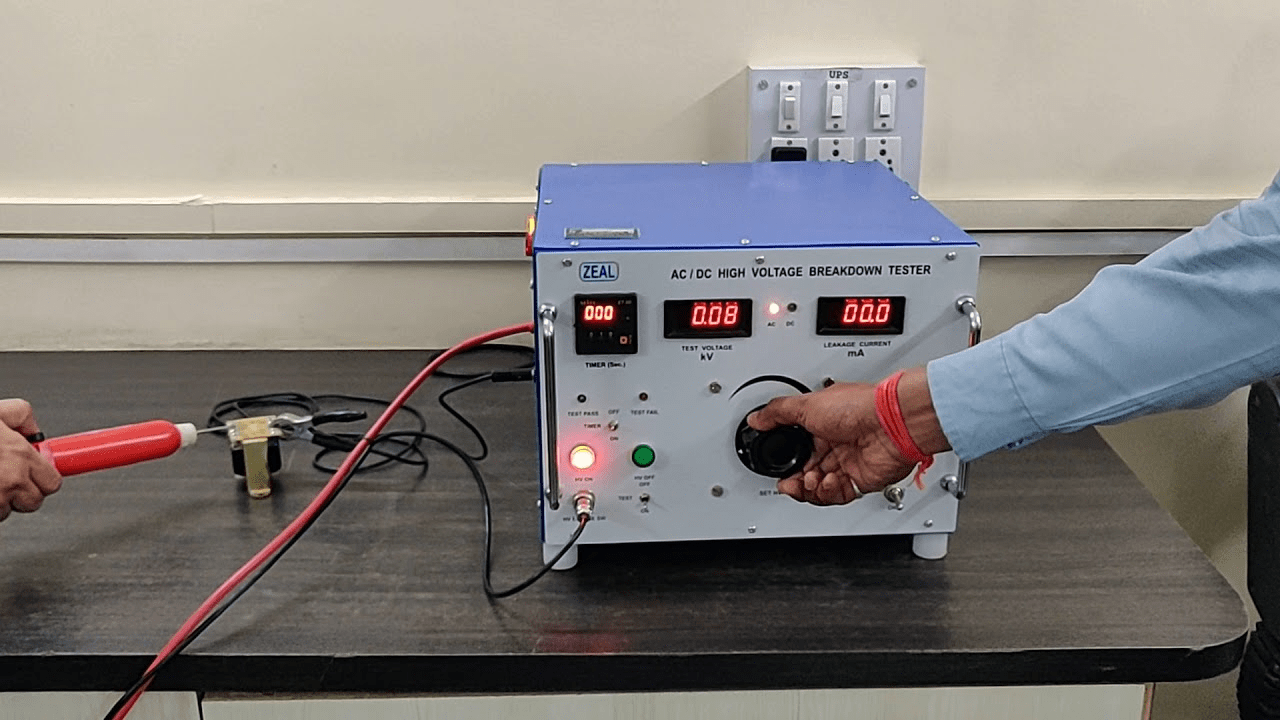

High voltage testing methods are diverse, each tailored to specific applications within power distribution systems. Among the most common techniques is the Direct Current (DC) testing, which subjects insulation materials to a steady voltage, revealing potential weaknesses and degradation over time.

Alternating Current (AC) testing, on the other hand, mimics real operating conditions and effectively simulates the stresses that equipment will encounter during normal use. Insulation Resistance Testing—often conducted as a quick diagnostic—measures the resistance of insulation materials, providing critical insights into their reliability.

Then there’s Partial Discharge (PD) testing, a sophisticated method that detects early signs of insulation failure by identifying small electrical discharges within the material.

Finally, Withstand Voltage testing pushes equipment to its limits, applying a voltage higher than normal operating conditions to ensure extreme reliability. These methods, while fundamentally different, converge on a singular goal: ensuring the safety and longevity of electrical systems vital to modern infrastructure.

Dielectric Withstand Testing

Dielectric withstand testing, often a pivotal aspect of high voltage (HV) testing, serves as a critical safeguard for electrical systems. This method involves subjecting electrical insulation materials and components to voltage levels significantly beyond their normal operating conditions to ensure they can withstand potential surges and prevent catastrophic failures.

During the testing process, variables such as temperature, humidity, and material composition are meticulously monitored, as they can greatly influence a systems dielectric strength. A successful dielectric withstand test not only confirms the integrity and durability of insulation systems but instills confidence in their performance under distressing conditions.

By identifying weaknesses before they can manifest into serious faults, this testing method becomes indispensable in the maintenance of reliable power distribution networks, safeguarding both equipment and personnel while ensuring operational efficiency.

Conclusion

In conclusion, high voltage testing plays a crucial role in ensuring the reliability and safety of power distribution systems. By employing various methods such as power frequency testing, impulse testing, and DC testing, utilities can effectively assess the integrity of equipment and identify potential weaknesses before they lead to failures.

Each testing method has its unique advantages and applications, tailored to specific components and operational environments within the power distribution network.

As advancements in technology continue to emerge, the importance of high voltage testing will only grow, providing essential insights that help maintain efficiency, prevent outages, and promote the longevity of electrical infrastructure. Ultimately, a robust HV testing regimen is vital for safeguarding both assets and the end consumers who rely on a stable power supply.